Introduction

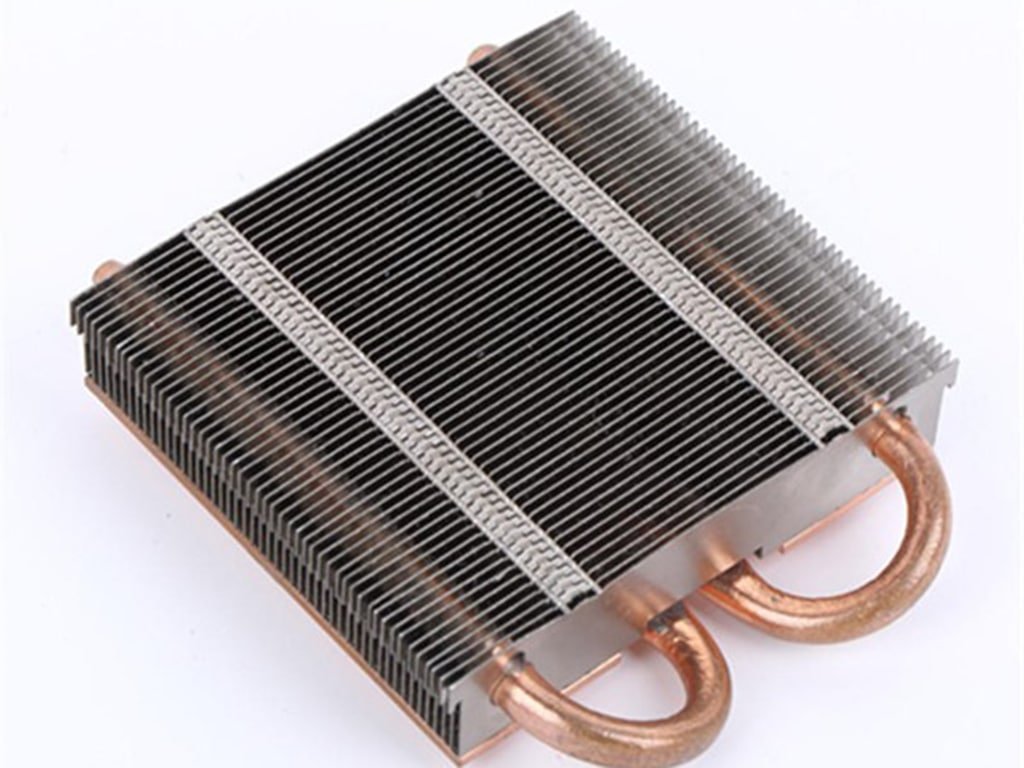

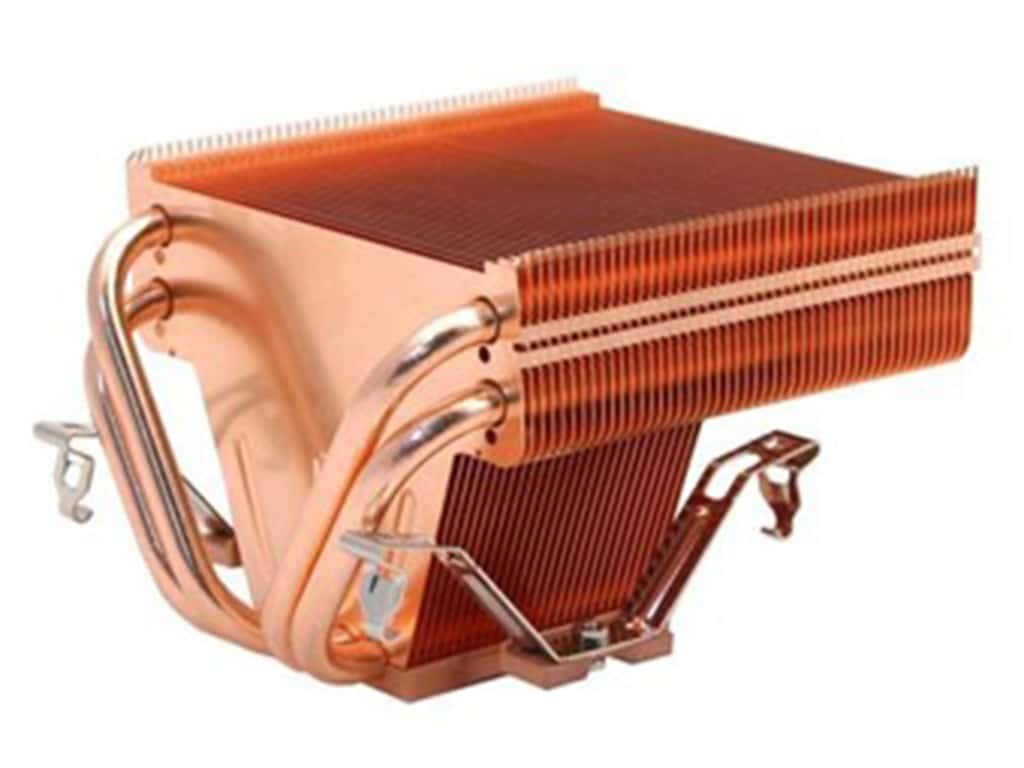

Copper zipper-fin heat sinks are produced by stamping thin copper sheets into interlocking fin segments, then assembling them into a compact fin stack.

This method provides excellent airflow performance with lower material usage compared to solid copper blocks or skived designs.

Zipper fins are especially suitable for medium-to-large heat sinks, telecom cooling modules, and heat sinks integrated into housings where weight and cost must be balanced without sacrificing performance.